Custom Probes, Headstages, and Cabling

The goal of this project was to acquire linear probes capable of

simultaneous recording and stimulation. My role in the project was to

develop a design specification based on the project requirements, to

design hardware or outsource the design where appropriate, and to work with

vendors to source the custom hardware elements needed.

In broad strokes, project execution was as follows:

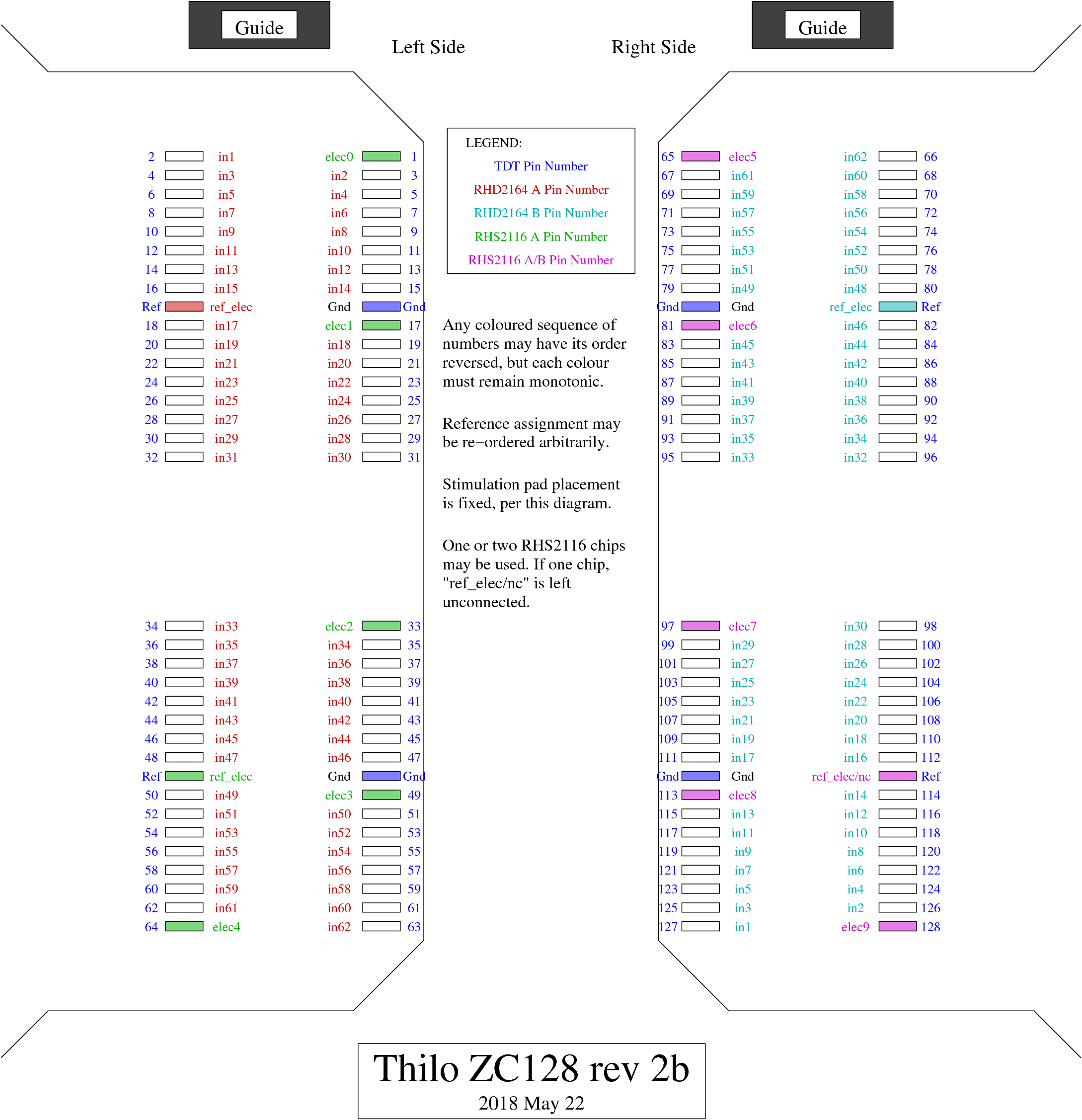

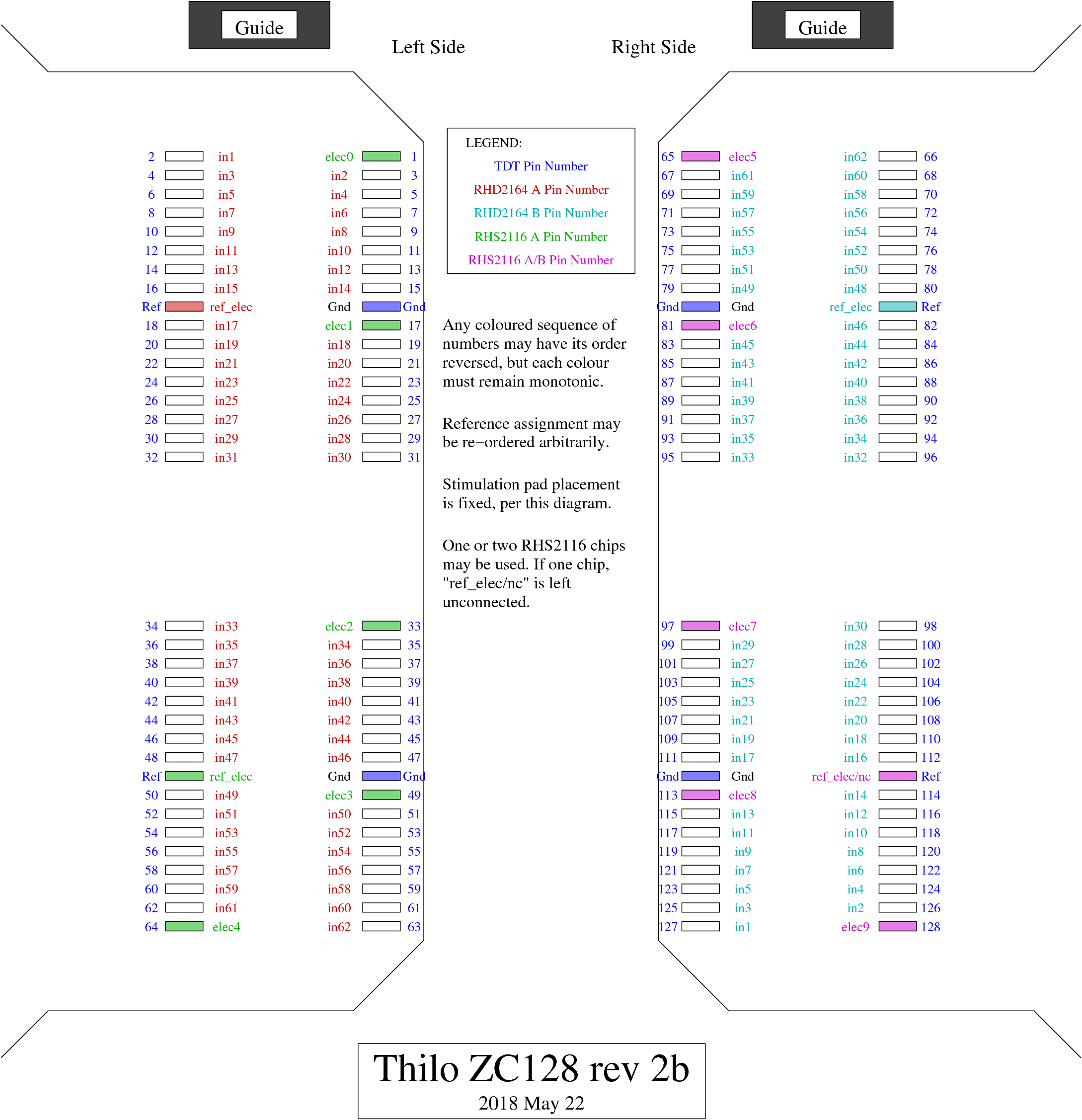

- Project requirements specified Intan Technologies recording and

stimulation controllers, headstages with Tucker-Davis Technologies ZIF-Clip

128 form factor, and custom 64- or 128-channel probes from several vendors.

The headstages needed to be far enough away from the probes that many probes

could be used with each experiment without mechanical conflict.

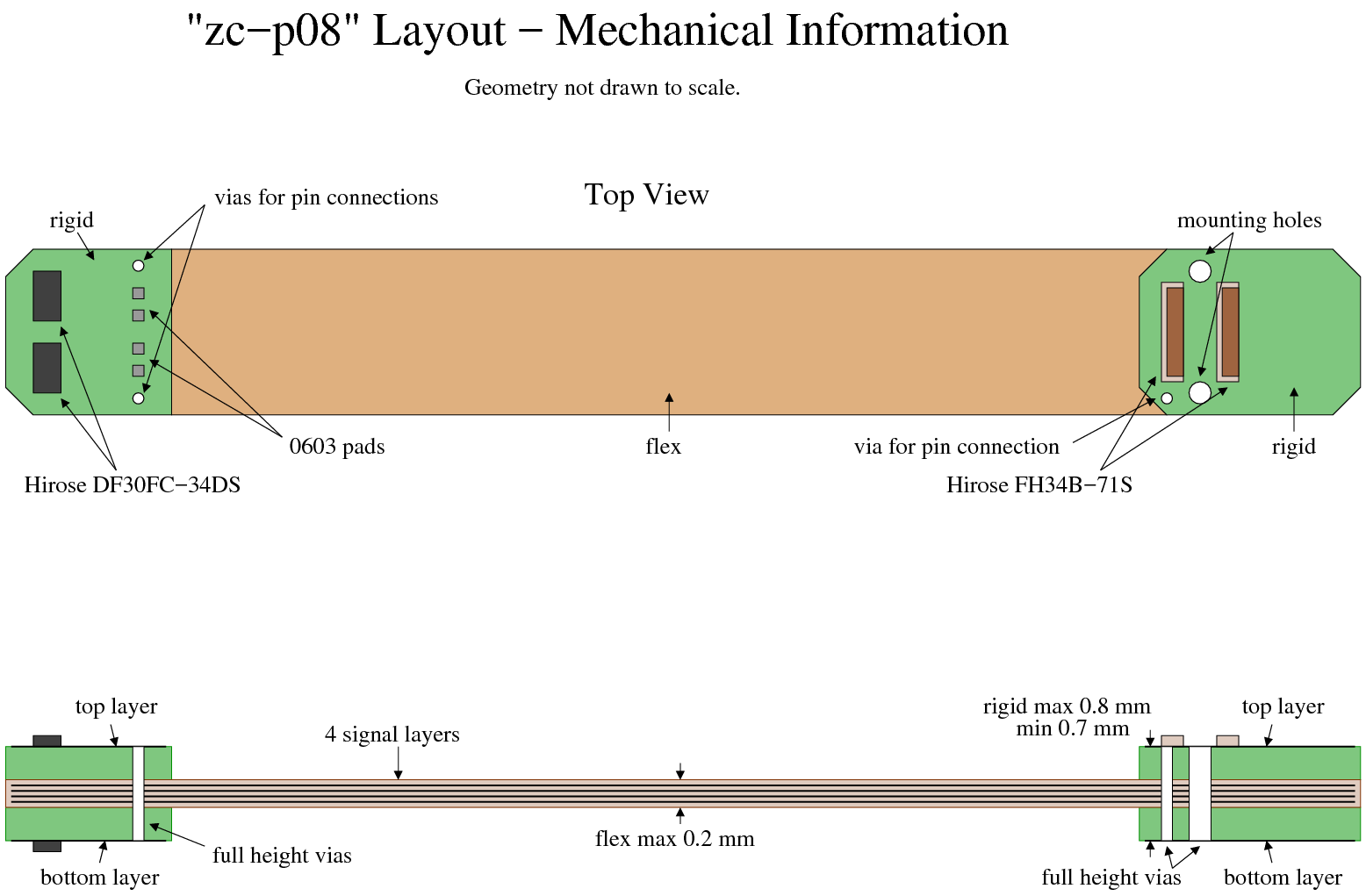

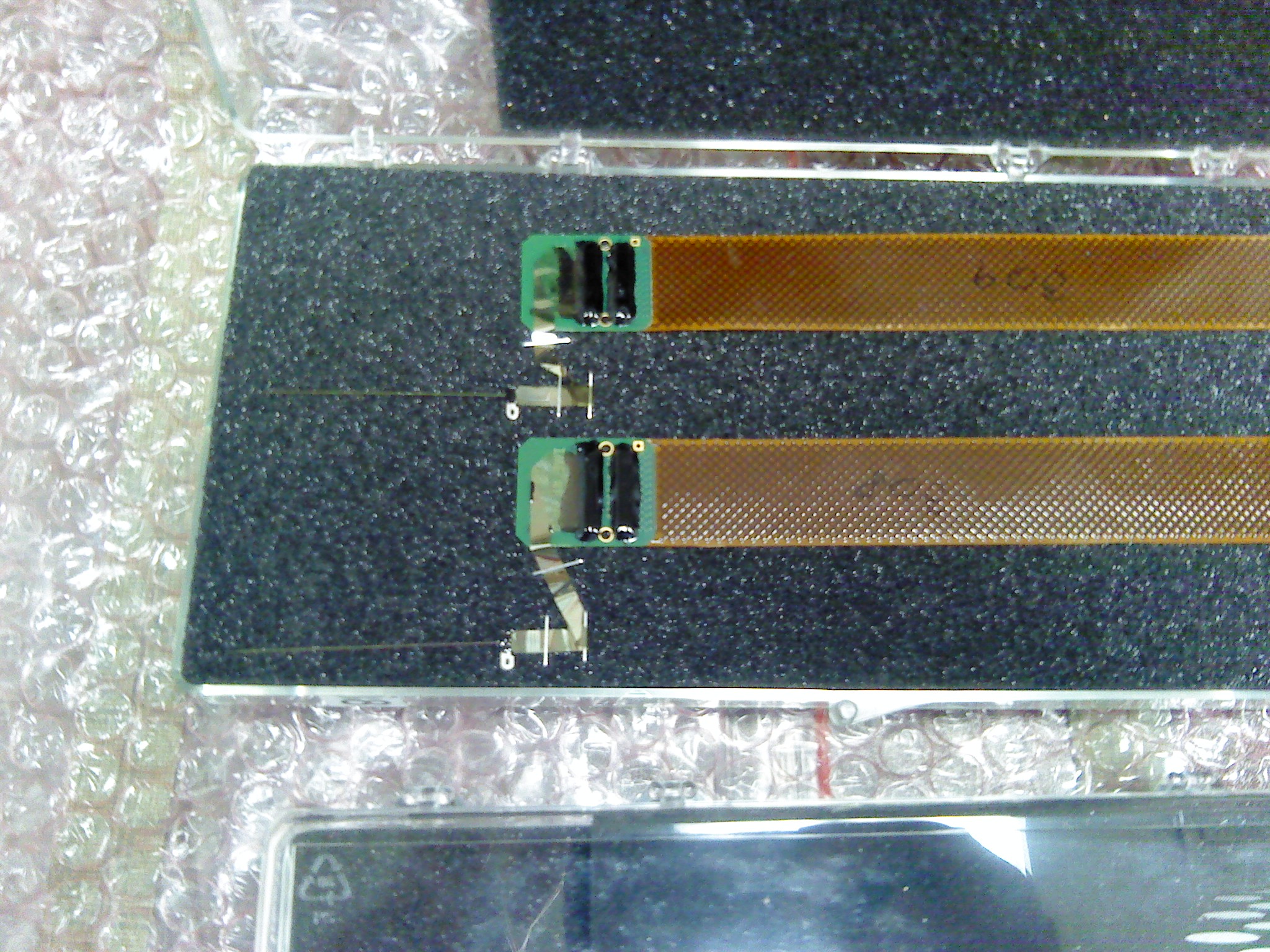

- I designed a cabling arrangement with shielded "heavy flex" adapting the

headstage to an intermediate connector and unshielded "thin flex" adapting

the probes to the intermediate connector. I defined the interfaces between

the thin flex and heavy flex and between the headstage and the heavy flex,

and between the headstages and the Intan recording and stimulation equipment.

- Headstage layout and fabrication was contracted to Tucker-Davis.

- I designed the "heavy flex".

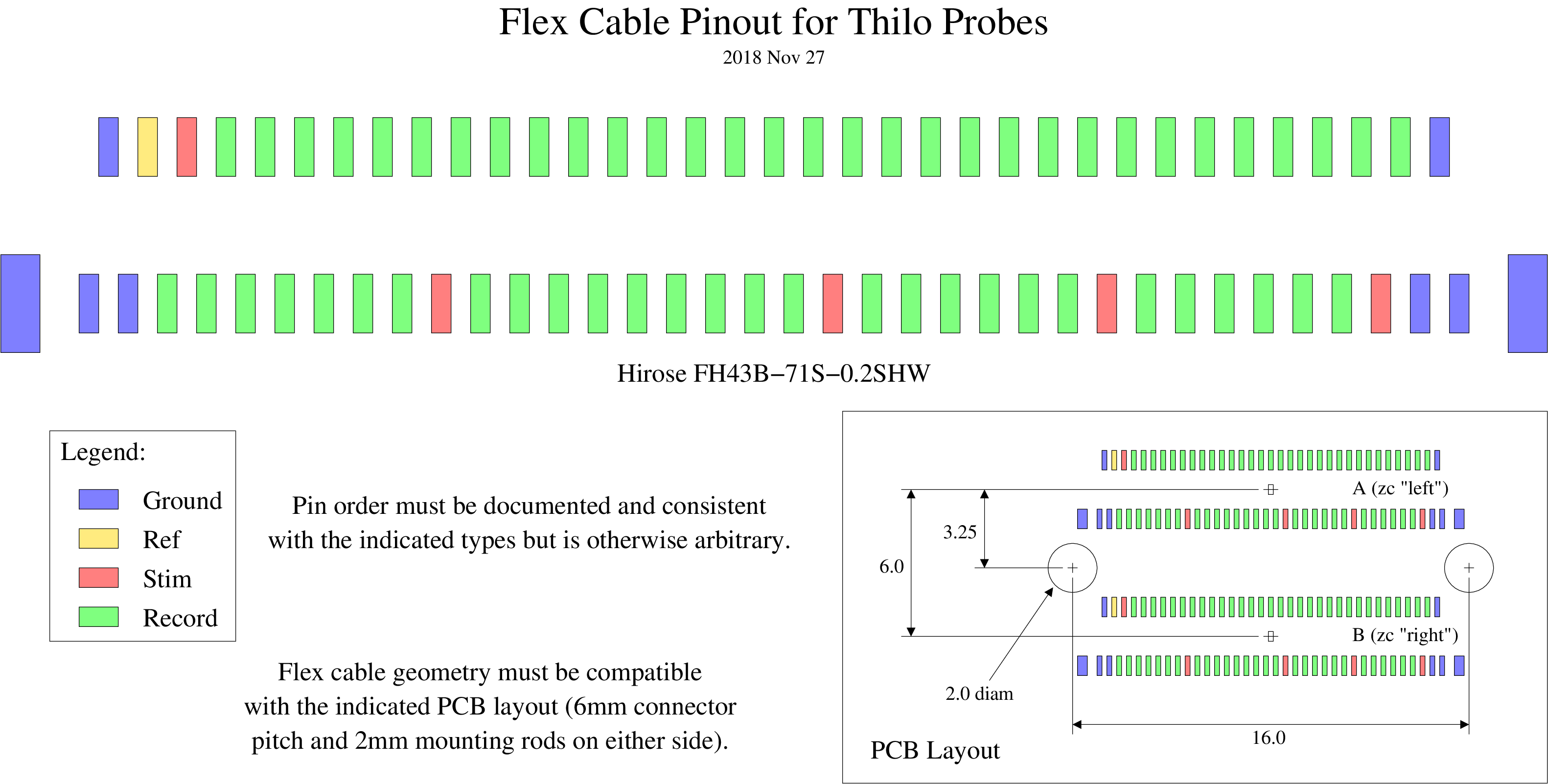

- I coordinated with probe vendors to finalize the specification of the

probes and of the cabling for each probe. Two probe vendors each designed

their own "thin flex". A third vendor designed their own cabling that mated

with the "ZIF-Clip" directly.

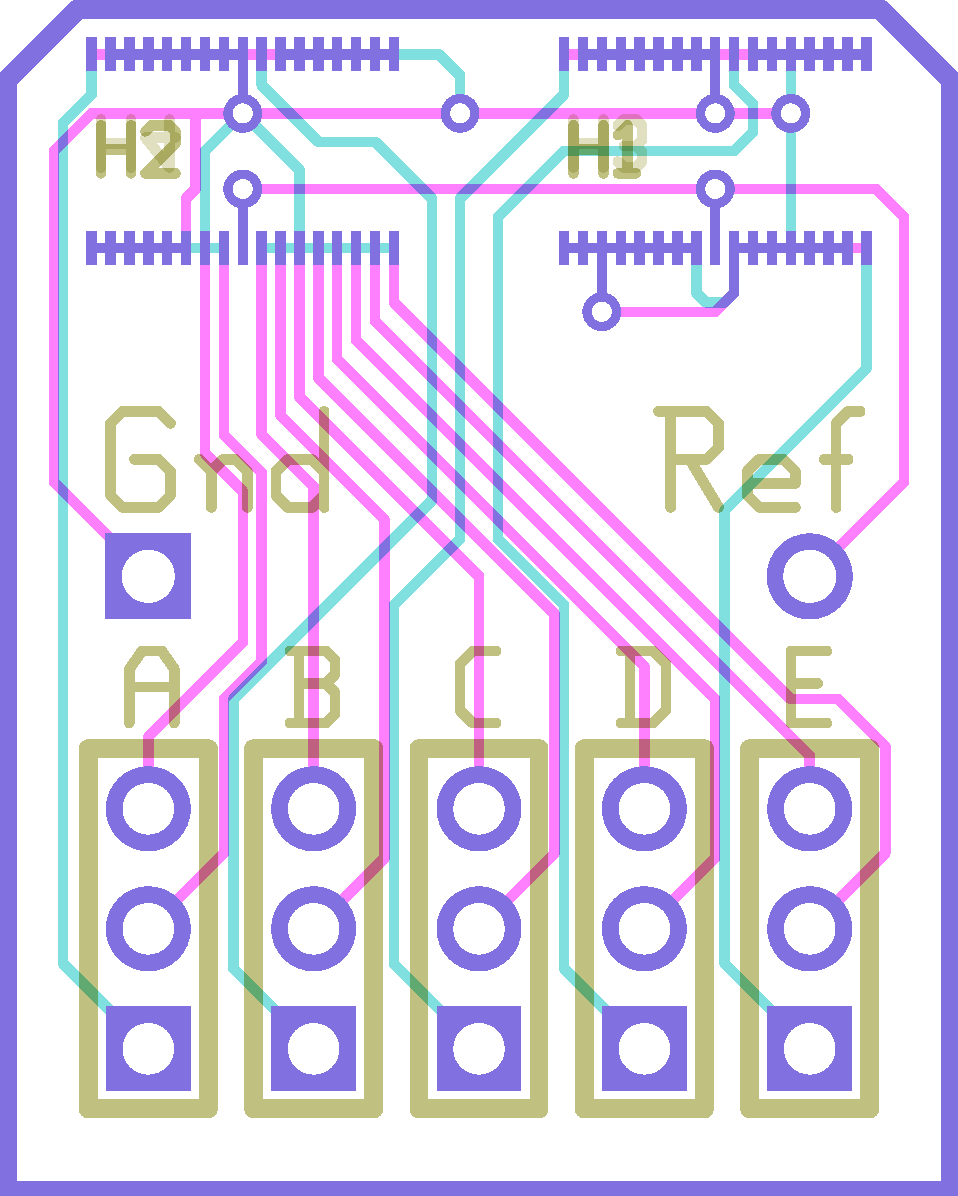

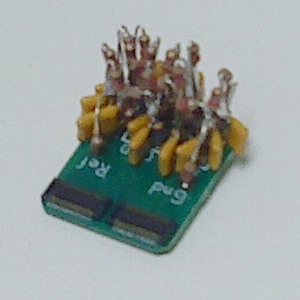

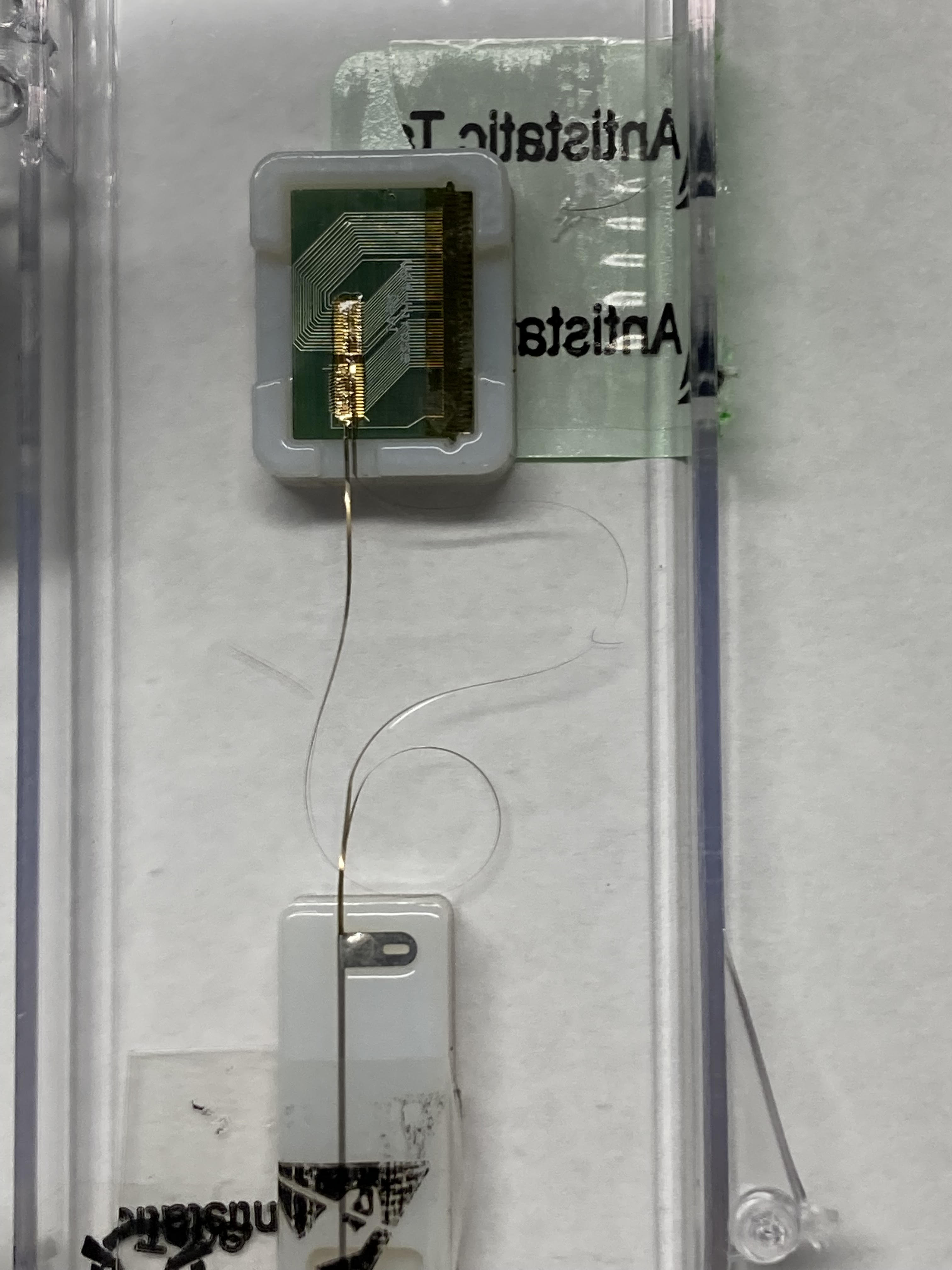

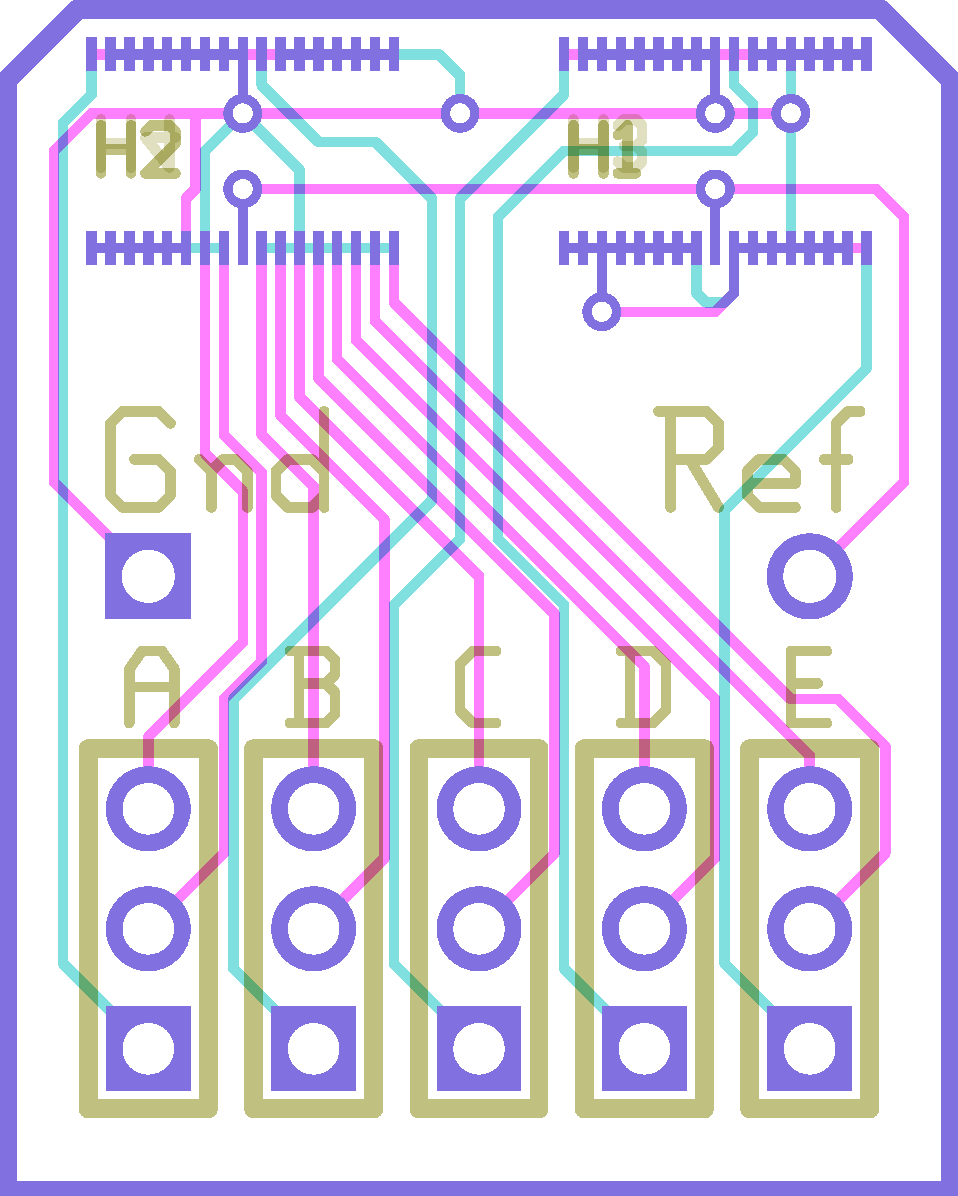

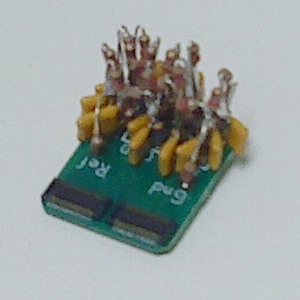

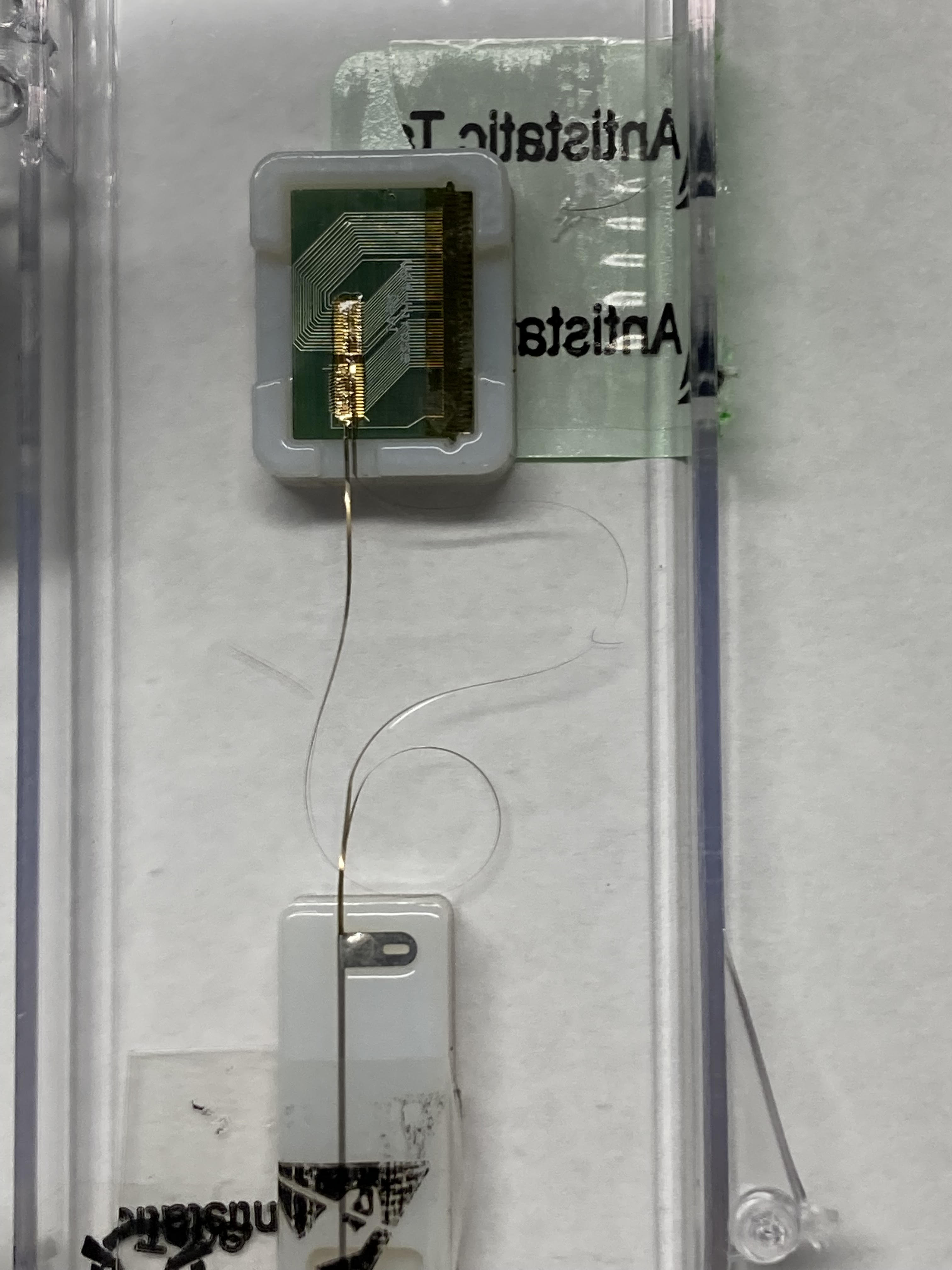

- I designed an electrode interface board (EIB) that allowed connection of

tungsten wire probes to the "ZIF-Clip" headstages.

- I performed integration testing and verified that the combination of

elements was electrically and mechanically compatible with the experiment

setup.

The headstages, cabling, and probes functioned as-intended, and they remain

in service.

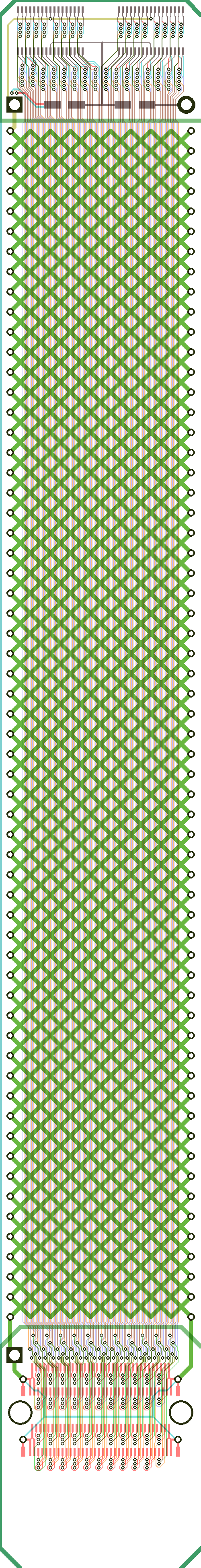

ZIF-Clip Design Specification

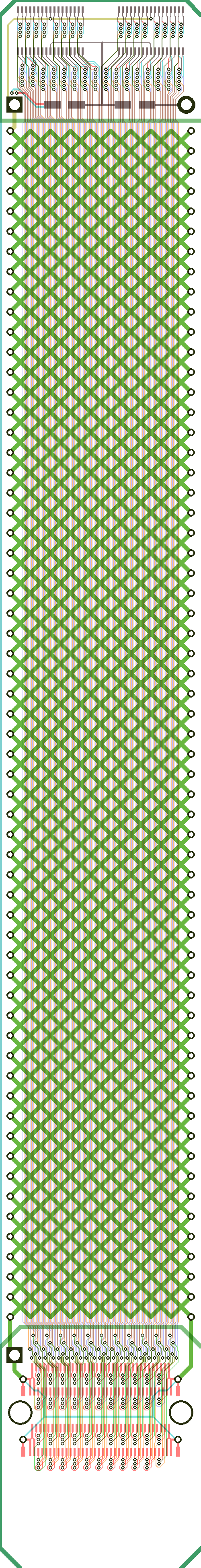

Heavy Flex Design and Implementation

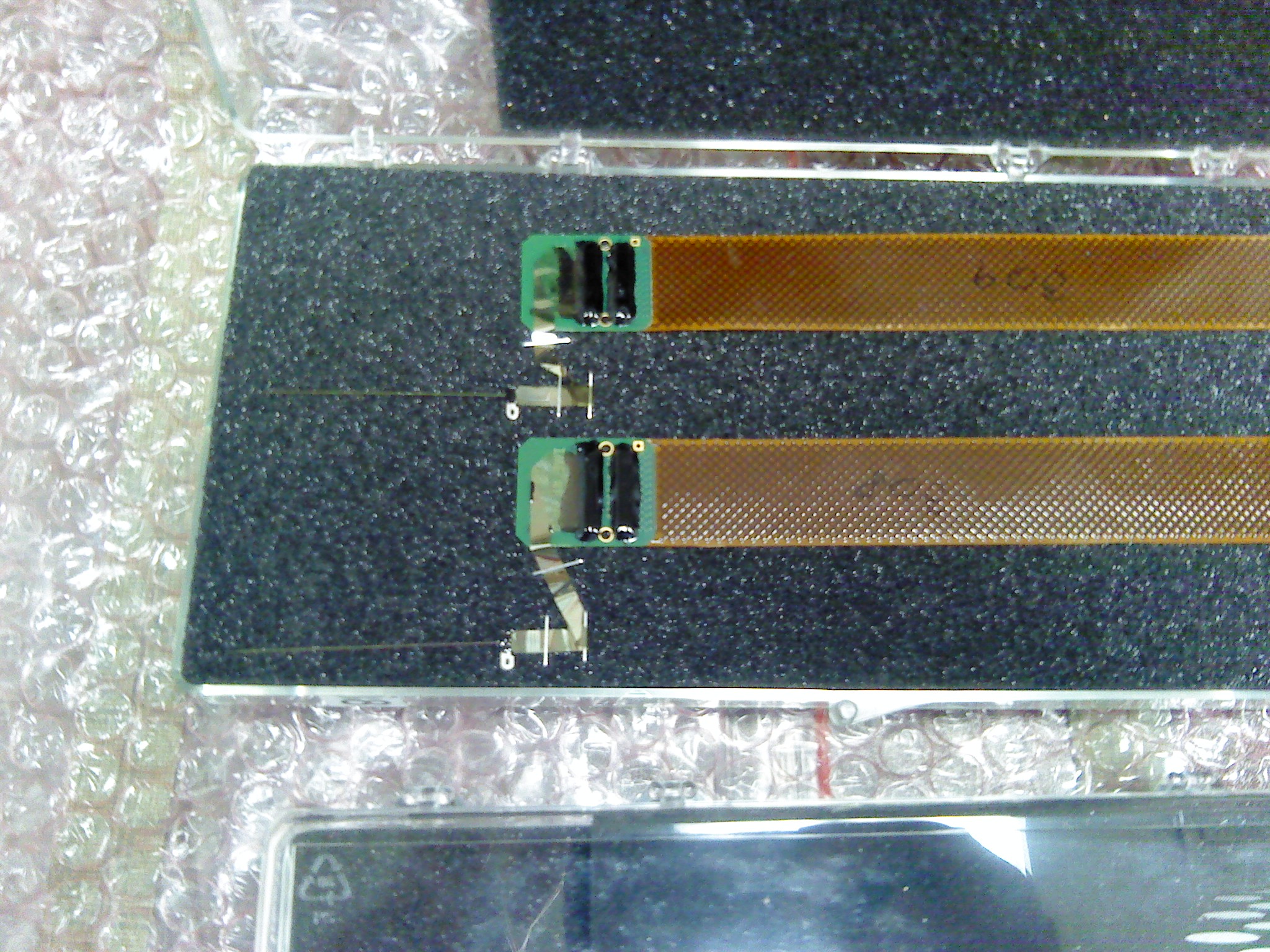

Probes With Thin Flex

Electrode Interface Boards